Travelling grate stoker

Price 20000.0 INR/ Number

Travelling grate stoker Specification

- Material

- Cast Iron

- Application

- Industrial Boilers, Steam Generating Plants

- Chemical Composition

- High Carbon Alloyed Iron

- Shape

- Rectangular/Grate Form

- Hardness

- 170-240 HB

- Density

- 7.2 Gram per cubic centimeter(g/cm3)

- Surface Treatment

- Heat Treated / Annealed

- Lifespan

- 5-10 years depending on usage

- Mounting Type

- Bolted or Welded

- Temperature Resistance

- Up to 1050°C

- Finish

- Smooth/Polished

- Size

- Custom sizes as per requirement

- Thickness

- 12 mm to 45 mm

- Grate Bar Spacing

- Standard and adjustable options

- Load Capacity

- Heavy duty, up to 2000 kg per assembly

- Corrosion Resistance

- Good, provided by alloying elements

Travelling grate stoker Trade Information

- Minimum Order Quantity

- 10 Number

- FOB Port

- Pune

- Supply Ability

- 100 Per Week

- Delivery Time

- 9 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Travelling grate stoker

We offer high-quality Carbon Stoker Bushes made from copper impregnated carbon grade, designed to withstand high temperatures and harsh operating environments. Our products

are suitable for use in boilers manufactured by leading OEMs and ensure optimal

performance and durability.

Thermax Limited

ISGEC Heavy Engineering Limited

Walchandnagar Industries Limited

Cheema Boiler Limited

Uttam Energy and many more.

Five Cail KCP

Customizable for Diverse Industrial Uses

Our travelling grate stokers can be precisely tailored to your specifications, including thickness, size, grate bar spacing, and mounting style. Designed for optimal performance in industrial boilers and steam generating units, these grates fit a range of plant requirements. Our expert team assists customers in selecting or designing the right stoker configuration to maximize operational efficiency and longevity.

Exceptional Heat and Load Endurance

Built from high carbon alloyed cast iron, each grate stoker withstands temperatures up to 1050C and handles loads of up to 2000 kg per assembly. The heat treatment and annealing processes ensure dimensional stability and prolong service life. These features, combined with the smooth or polished finish, make our stokers a reliable choice for demanding environments.

Corrosion Resistance and Long Service Life

Advanced alloying elements impart excellent corrosion resistance to our travelling grate stokers, even under aggressive operating conditions. With a durability range of 5-10 years based on usage, customers benefit from reduced maintenance intervals and consistent performance. The design ensures efficient combustion, leading to better fuel economy and lower operational costs.

FAQs of Travelling grate stoker :

Q: How does the travelling grate stoker enhance industrial boiler efficiency?

A: The travelling grate stoker provides uniform fuel distribution and optimized airflow, which leads to improved combustion efficiency in industrial boilers. Its adjustable grate bar spacing and heat-treated construction help maintain steady operation, resulting in better fuel utilization and reduced emissions.Q: What process is involved in the heat treatment of these grate stokers?

A: Our grate stokers undergo a controlled heat treatment or annealing process, enhancing their hardness, mechanical strength, and resistance to thermal stresses. This process ensures more reliable performance, especially in high-temperature and high-load environments.Q: When should the grate stoker be replaced to maintain optimal performance?

A: Typically, the lifespan of our travelling grate stoker ranges from 5 to 10 years, depending on operating conditions and maintenance. Replace the grate when you notice significant wear, deformation, or reduced combustion efficiency to avoid unplanned downtime.Q: Where can these travelling grate stokers be installed?

A: Our stokers are ideally suited for use in industrial boilers, steam generating plants, and other high-capacity thermal applications. They can be mounted with either bolted or welded setups, making installation flexible to different system designs.Q: What benefits do alloying elements provide in the grate stoker material?

A: Alloying elements in the high carbon cast iron composition enhance the stokers corrosion resistance, durability, and temperature tolerance. This means longer service life and less frequent replacement, which is cost-effective for industrial operations.Q: How should the grate stoker be maintained for prolonged lifespan?

A: Regular inspection, cleaning, and removal of ash or clinker buildup help maintain the grates performance. Ensure all mounting bolts or welds are secure, and promptly address any signs of excessive wear or corrosion to extend service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Bush Category

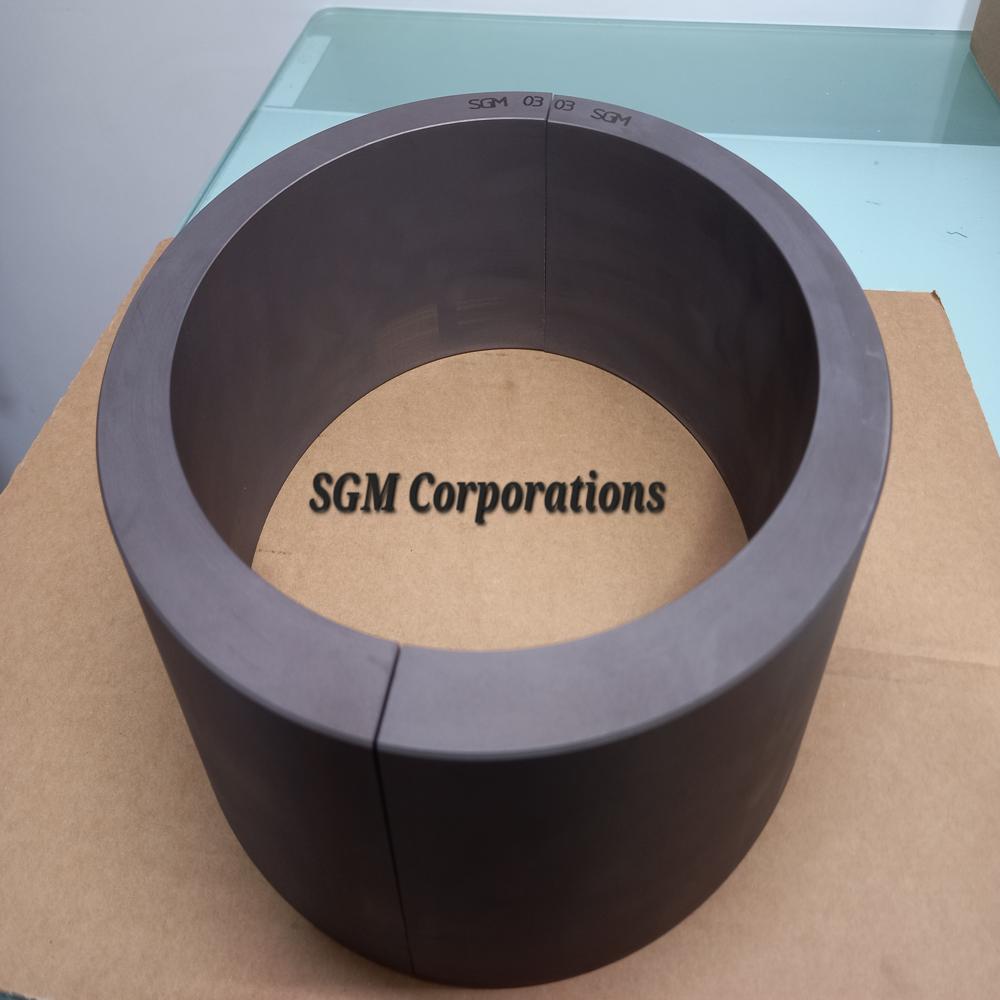

stoker bush

Price 22000.0 INR / Number

Minimum Order Quantity : 1 Set

Usage : Copper Impregnated Graphite Bearings For Sugar Plants Power generation plant

Color : Black

Material : Carbon Graphite

Application : Cogen plant

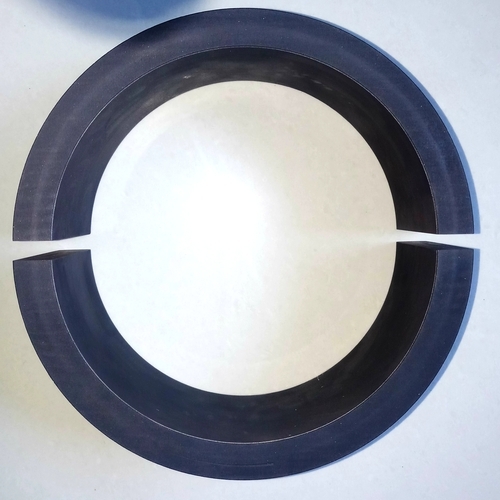

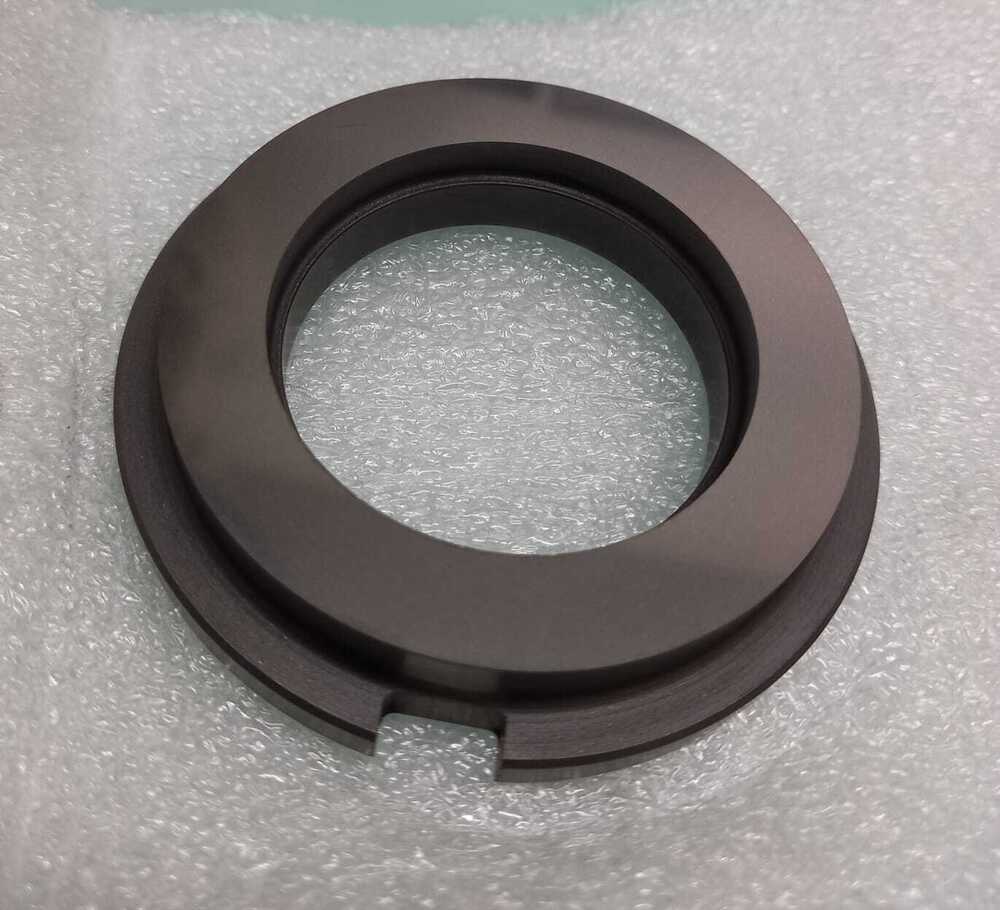

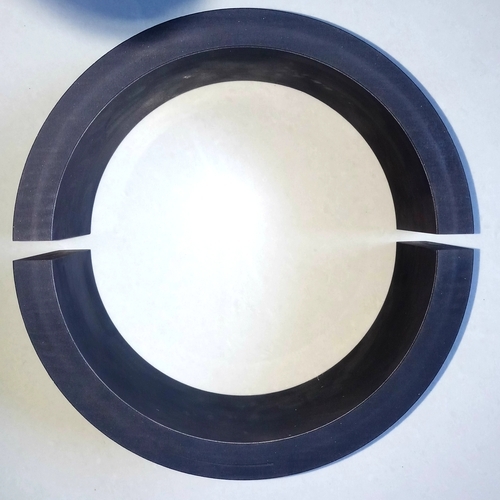

Water Pump Carbon Seal

Price 1500.0 INR / Number

Minimum Order Quantity : 10

Usage : sealing

Color : Black

Material : Antimony impregnated carbon seal

Application : water pump of EMD locomotive

Submersiable pump carbon buhs

Price 100.0 INR / Unit

Minimum Order Quantity : 10

Usage : submersiable pump

Color : black

Material : Carbon Graphite

Application : Water

Submersiable Pump Carbon Bush

Price 75 INR / Unit

Minimum Order Quantity : 10

Usage : Submersiable Pump

Color : Black

Material : Carbon Bush

Application : Carbon

|

SGM CORPORATIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry