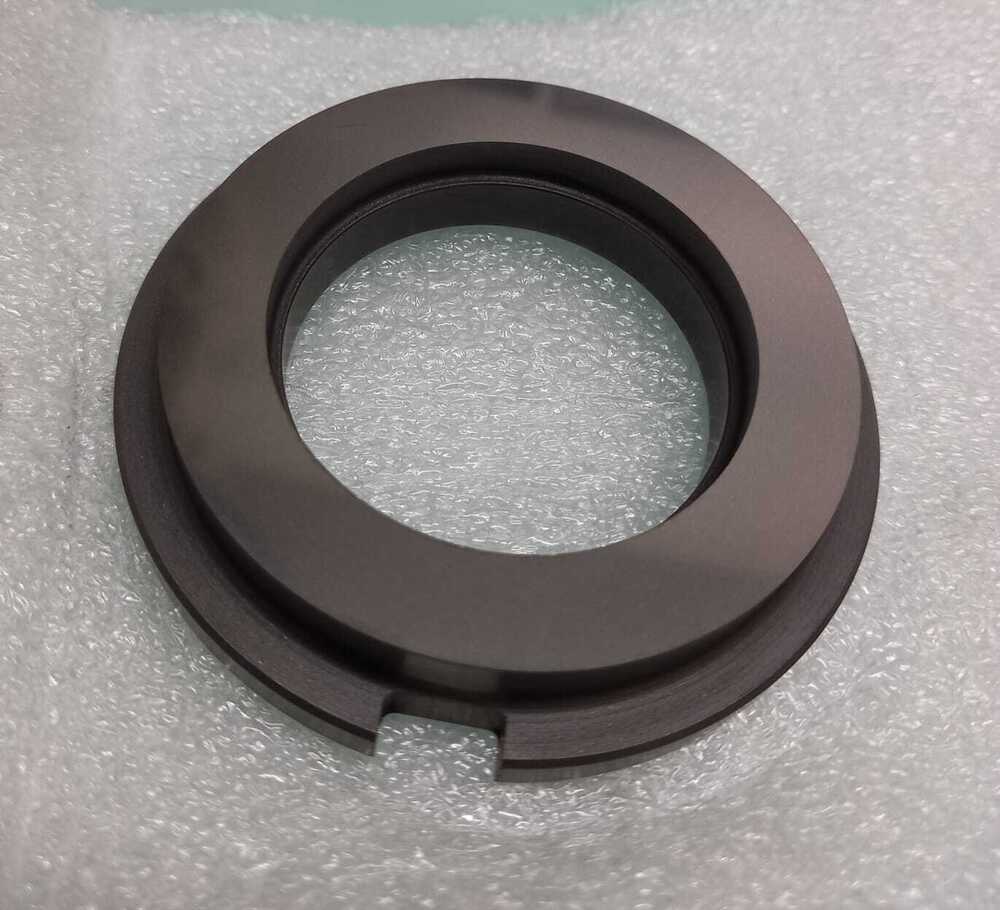

stoker bush

Price 22000.0 INR/ Number

MOQ : 1 Set

stoker bush Specification

- Usage

- Copper Impregnated Graphite Bearings For Sugar Plants Power generation plant

- Material

- Carbon Graphite

- Size

- 165x127x150 mm

- Application

- Co-gen plant

- Height

- 165 Millimeter (mm)

- Chemical Composition

- Copper Impregnated

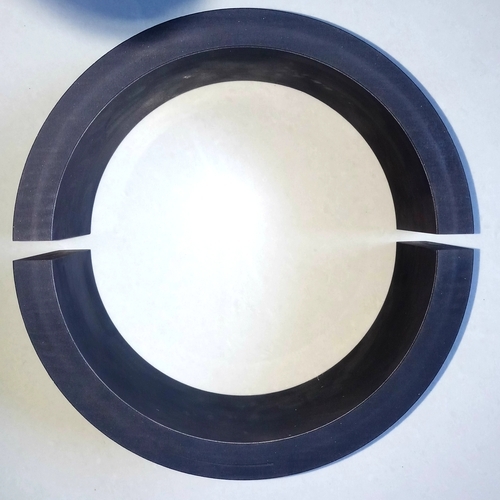

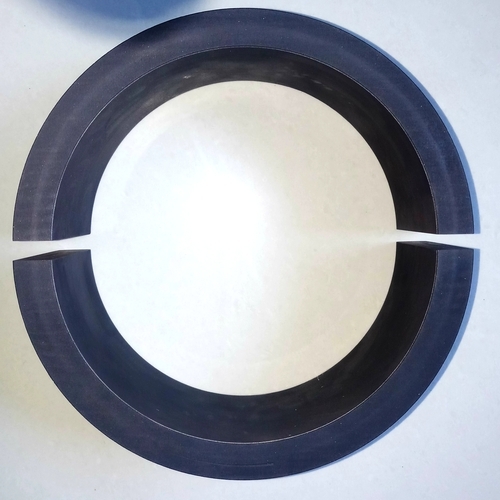

- Shape

- Round

- Product Type

- Carbon Graphite Carbon bush beCopper Impregnated Carbon Bush Bearing Travelling grate boiler.

- Weight

- 3 Kilograms (kg)

- Color

- Black

- Hardness

- 105

- Width

- 127 Millimeter (mm)

- Density

- 2.8 Gram per cubic centimeter(g/cm3)

- Length

- 150 Millimeter (mm)

stoker bush Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard

- Main Domestic Market

- All India

About stoker bush

Carbon Graphite Carbon bush bearing with Copper ImpregnatedCopper Impregnated Carbon bush bearing

- Thermax Limited

- ISGEC Heavy Engineering Limited

- Walchandnagar Industries Limited

- Cheema Boiler Limited

- Uttam Energy and many more.

Precision Engineering for Power Plants

Specially designed for co-generation plants, this copper-impregnated graphite stoker bush addresses critical requirements for longevity and performance in sugar plant power generation. Its build quality, shape, and size are tailored for seamless integration and operation, ensuring efficient energy production and reduced downtime.

Material Advantage: Copper Impregnated Carbon Graphite

The fusion of carbon graphite and copper raises this stoker bush above standard components. The combination increases both mechanical strength and thermal conductivity, providing excellent wear and corrosion resistance ideal for challenging plant conditions.

FAQs of stoker bush:

Q: How is the copper-impregnated stoker bush used in co-generation plants?

A: This stoker bush serves as a critical bearing component in the machinery of co-generation plants, specifically within power generation systems in sugar plants. It enables smooth rotation and supports moving parts, resulting in higher efficiency and prolonged equipment lifespan.Q: What is the benefit of using carbon graphite material with copper impregnation?

A: Copper impregnation enhances the already beneficial properties of carbon graphite by improving thermal conductivity, reducing wear, and boosting overall durability. This combination results in higher performance and minimal maintenance in power generation equipment.Q: When should the stoker bush be replaced in power generation applications?

A: Replacement is typically based on regular maintenance schedules or when signs of excessive wear or decreased performance are observed. Periodic inspections ensure optimal system operation and prevent unexpected equipment failures.Q: Where can this stoker bush be utilized besides co-generation plants?

A: While optimized for co-generation and sugar plant power generation systems, its robust material characteristics allow for usage in various industrial environments requiring reliable and efficient carbon graphite bearings, such as cement, chemical processing, and metal industries.Q: What is the manufacturing process for this round copper-impregnated stoker bush?

A: The stoker bush is produced by shaping high-density carbon graphite into a round form, followed by a process of copper impregnation. This enhances its mechanical and thermal properties, tailored to withstand demanding operational conditions.Q: What advantages does the stoker bushs shape and size offer?

A: The precise round shape and standardized dimensions (165x127x150 mm) ensure compatibility and a consistent fit in co-generation plant systems. These features simplify installation and contribute to stable and effective performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Graphite Bush Category

Water Pump Carbon Seal

Price 1500.0 INR / Number

Minimum Order Quantity : 10

Color : Black

Usage : sealing

Material : Antimony impregnated carbon seal

Shape : Round

Submersiable pump carbon buhs

Price 100.0 INR / Unit

Minimum Order Quantity : 10

Color : black

Usage : submersiable pump

Material : Carbon Graphite

Shape : round

Travelling grate stoker

Price 20000.0 INR / Number

Minimum Order Quantity : 10

Material : Cast Iron

Shape : Rectangular/Grate Form

Submersiable Pump Carbon Bush

Price 75 INR / Unit

Minimum Order Quantity : 10

Color : Black

Usage : Submersiable Pump

Material : Carbon Bush

Shape : Round

|

SGM CORPORATIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry